Packaging Professionals, Why Visiting a Recycling Facility Can Benefit You

Gaining a better understanding of the recycling process.

“How can I make my packaging more sustainable?” This is the question most frequently asked by our clientele. The answer, however, is often ambiguous. Is the brand looking to detach itself from fossil fuels or plastics? Are they searching for something consumers will perceive as sustainable? Or, are they unsure and simply trying to comply with the sustainability goals their company has openly stated to the public?

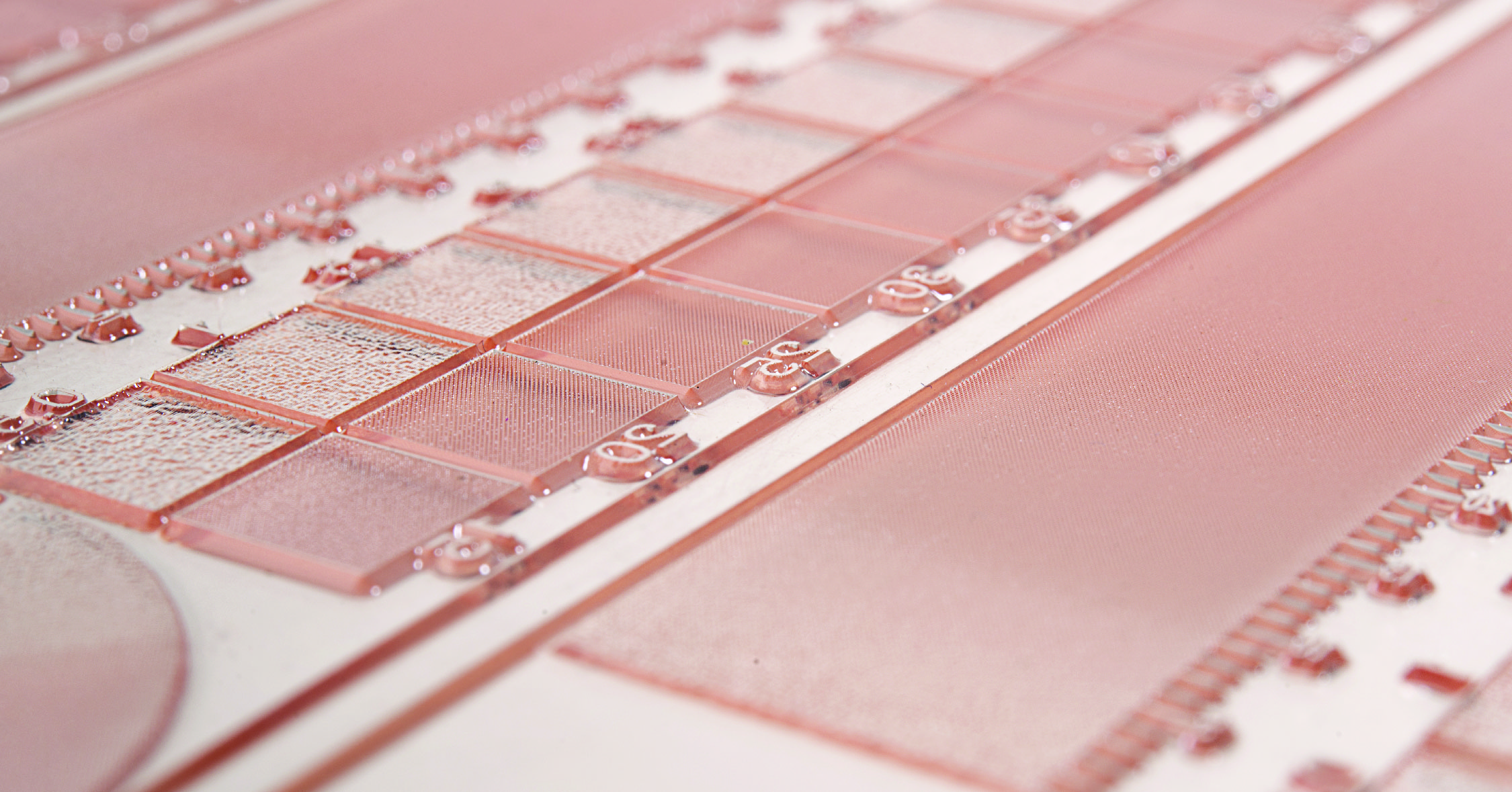

Whatever the case, it is essential to design packaging not only for its intended use, but for its end of life. For many of us packaging professionals, we don’t always know what that end of life looks like. So, in the spirit of understanding, to educate ourselves, a few of us at Haney decided to find out for ourselves and take a trip to our local material recovery facility, Rumpke Recycling.

*Our tour was taken pre-pandemic. Due to the Coronaviris, tours, presentations and Rumpke’s participation at community events has been suspended until further notice.

What is a Material Recovery Facility?

A material recovery facility or MRF is a specialized plant that processes commingled recyclables, sorts them by type and then markets the materials to end-use manufacturers that recycle them into new, usable products. In a perfect, circular economy, these products are sold to consumers and recycled again, and again.

It is necessary to understand a MRFs capabilities vary city to city and challenges to those facilities can arise in a myriad of ways; materials being recycled may be contaminated, new forms of packaging are continually being developed and introduced into the waste stream, and the value of the materials a MRF is designed to recover and sell can drop suddenly due to economic or social shifts.

As a key component of many residential and commercial single-stream recycling programs, MRFs play a pivotal role in the recovery and recycling of materials such as aluminum, PET, HDPE, and paper.

Locally, a 15-minute drive from the Haney facility, Rumpke is a regional company serving customers in Ohio, Kentucky, Indiana and West Virginia. They own and operate 14 landfills and 11 recycling facilities. The Cincinnati facility we visited is the 8th largest in the nation and is equipped with state -of-the art technology. This $32 million MRF was opened in the fall of 2013 and processes approximately 185,000 tons of recyclable materials each year.

Rumpke is unique in comparison to many other companies across the country as Anne Gray, education specialist at Rumpke explained to us, “Rumpke is the only waste and recycling company in the Midwest with a glass cleaning system that prepares post- consumer glass for the fiberglass and bottle glass manufacturing industries. Rumpke’s glass processing facility is in Dayton, Ohio so the glass coming to the Cincinnati and Columbus MRFs is transported to Dayton.”

Additionally, Rumpke sells 98% of the recyclable material they process domestically with the majority from the Cincinnati MRF being sold within a 250 to 300-mile radius.

How does the Rumpke MRF effectively sort through all these materials?

As a single stream recycling program, all recyclables are collected in a single container, either curbside, in dumpsters at businesses, apartment complexes, drop box locations, etc. The material is then transported to the MRF in St. Bernard, Ohio. Through a combination of incredible hand eye coordination, technologies, and an automated system of chutes and conveyers, 55 tons of recyclable materials are sifted through and sorted every hour.

Touring the facility, what impacted our team most was the number of people physically sorting through materials. So often we think of these processes as being solely automated, however, a multitude of sorters are located at numerous stations throughout the process each retrieving items that don’t belong, or could cause issues in the system, such as plastic bags… or Halloween masks and golf clubs!

Of the automated systems, some technologies are designed to shake and sift apart specific recyclables from the rest. For example, disk screeners send materials over spinning disks to propel larger items like cardboard along the line and allows smaller items to fall below to their own designated conveyer belt. In turn, angled sorters cause three dimensional items, for example, water bottles, to fall to the side, while flat items, as in paper, continue on to their destination. Additional technologies at work at Rumpke are overhead magnets that attract metal cans. An eddy current is used to separate aluminum cans, while optical scanners detect materials such as paper, plastic and cartons. Once items have been sorted they are pressed into bales which can weigh anywhere from 800 lbs (aluminum cans) to 2000 lbs (paper) then shipped to factories to be recycled.

A serious misconception when it comes to recycling is that some recyclable material placed in curbside bins will end up in a landfill, but Gray says that isn’t the case at Rumpke, “People should be assured that all acceptable material coming to our recycling facilities will truly be recycled. Rumpke is not landfilling any acceptable material. With events that have occurred internationally, especially with the loss of the markets in China, people are concerned that Rumpke may be landfilling acceptable material. We are not.”

Should the recycling process be considered during package design and development?

The short answer is, YES!

A product’s package has a tremendous job to do. Not only is it meant to protect the product and ensure it makes it to the consumer’s home intact and uncontaminated, it also must act as a vehicle to communicate key information to the buyer such as nutrition facts or safety instructions. It must do all this while touting eye-catching graphics critical to the First Moment of Truth (FMOT).

Many packages we see on shelf today, utilize the chasing arrows with Resin Identification Codes (RICs), on the product to indicate recyclability. But as Gray tells us, that isn’t the solution, “The triangular symbol containing a number on the bottom of plastic containers does not always mean that the container can be recycled or that it can be recycled everywhere. “At Rumpke, rather than telling the general population a number, they provide information on what shape of packaging can be collected, for example: “Rumpke instructs customers to evaluate the shape of the plastic container. If the top of the container is narrower than the base and has a screw lid, it is acceptable.”

Beyond ensuring that the materials a package is made from are recyclable, brands should confirm that the shape and size of their product will travel through the recycling process correctly. Otherwise, the product might inadvertently be rejected by the recycling process and discarded as waste.

Those designing new packaging formats should also take into consideration that just because a material can be recycled doesn’t mean there is an end market for its recycled form. “Companies should understand the technology used to separate recyclable material and that there are some limitations with the technology,” says Gray. “Companies should also understand the demands of the end markets.”

When asked if brands should consult Rumpke, or other MRFs, when designing packaging, Gray, explained that indeed, companies do consult them regarding packaging design. “This makes sense so Rumpke’s input can be considered when decisions are made.”

Instituting practices that contribute to packaging being recycled subsequently leads to less waste and a cleaner world. Educating individuals, especially those developing new formats, on the process, criteria and the use, if any, of end market recycled form, can positively impact the design and materials used. The key is knowing beforehand the probability of creating a recycled product that truly works in the system we have in place.

In conclusion, everyone should strive to have a more thorough understanding of what happens to the packaging they create, or use, once it serves its intended purpose.

Other Articles You Might Enjoy

Sustainability Snacks: Labeling a Smarter Future with UPM Raflatac