Sustainability is a key topic gaining momentum across all business units and industries. There is an increased demand from regulatory organizations to adopt measures to reduce environmental footprints and consumers are more conscious and making purchase decisions based on environmental factors.

As explained by Genara Andrade, New Business Development Leader at DuPont, “Flexographic printing, compared to traditional gravure printing, is a key ally to brand owners since there’s lower non-renewable energy use, less greenhouse gas emissions, and flexibility to print on multiple substrates.”

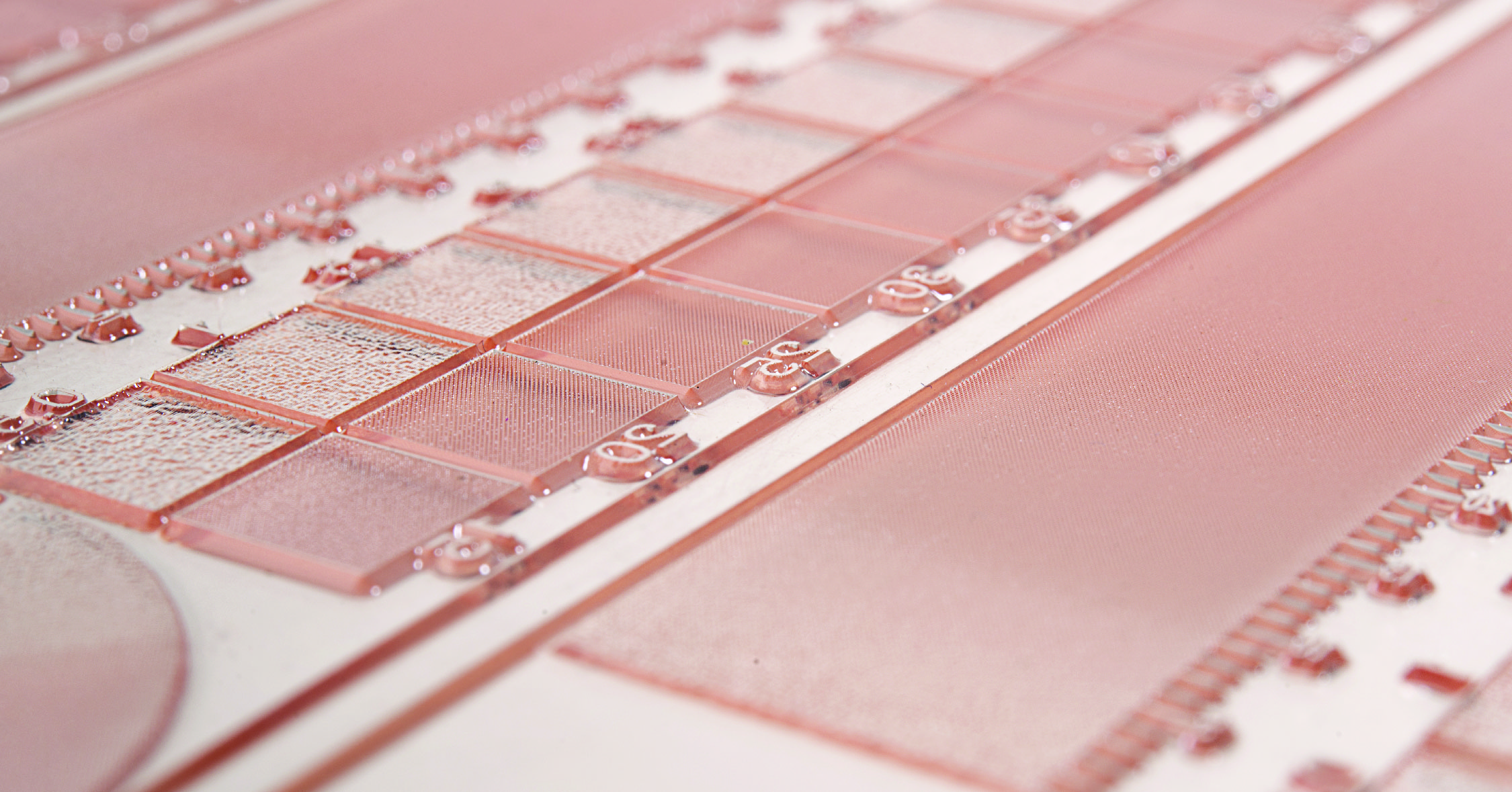

Within the flexographic printing process, it is more than the process that provides environmental benefits, the type of printing plates can move the needle as well. “The DuPont™ FAST® 2000TD is DuPont’s latest generation of our thermal equipment that offers a more sustainable platemaking process compared to the solvent workflow by completely eliminating the need for solvents during platemaking.”

Andrade provides two aspects of the thermal plate making system that make it more environmentally friendly:

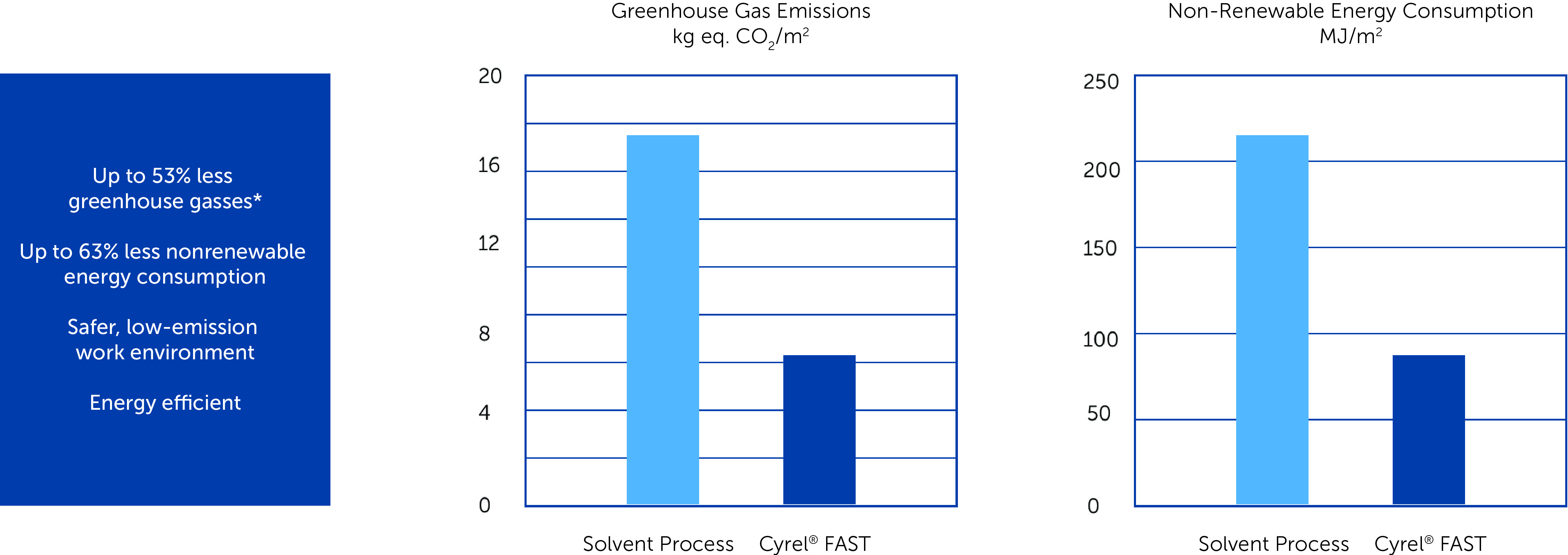

“The thermal system eliminates the need for solvent in the platemaking process, which is safer and provides a cleaner environment. And, by eliminating the solvent, the operation can save >50% greenhouse gas emissions during platemaking, meaning it has a significantly reduced carbon footprint compared to solvent-based processes.”

“DuPont continues to innovate DuPont™ Cyrel® FAST thermal systems and our latest generation of the DuPont™ FAST® equipment contains a Catox system that compared to previous versions, eliminates 99.7% VOCs in the platemaking exhaust and recovers the heat from the catalytic reaction to preheat the incoming exhaust. This, combined to the fact that it does not require plates to be dried, make the thermal workflow consume less energy, again lowering the carbon footprint compared to solvent systems.”