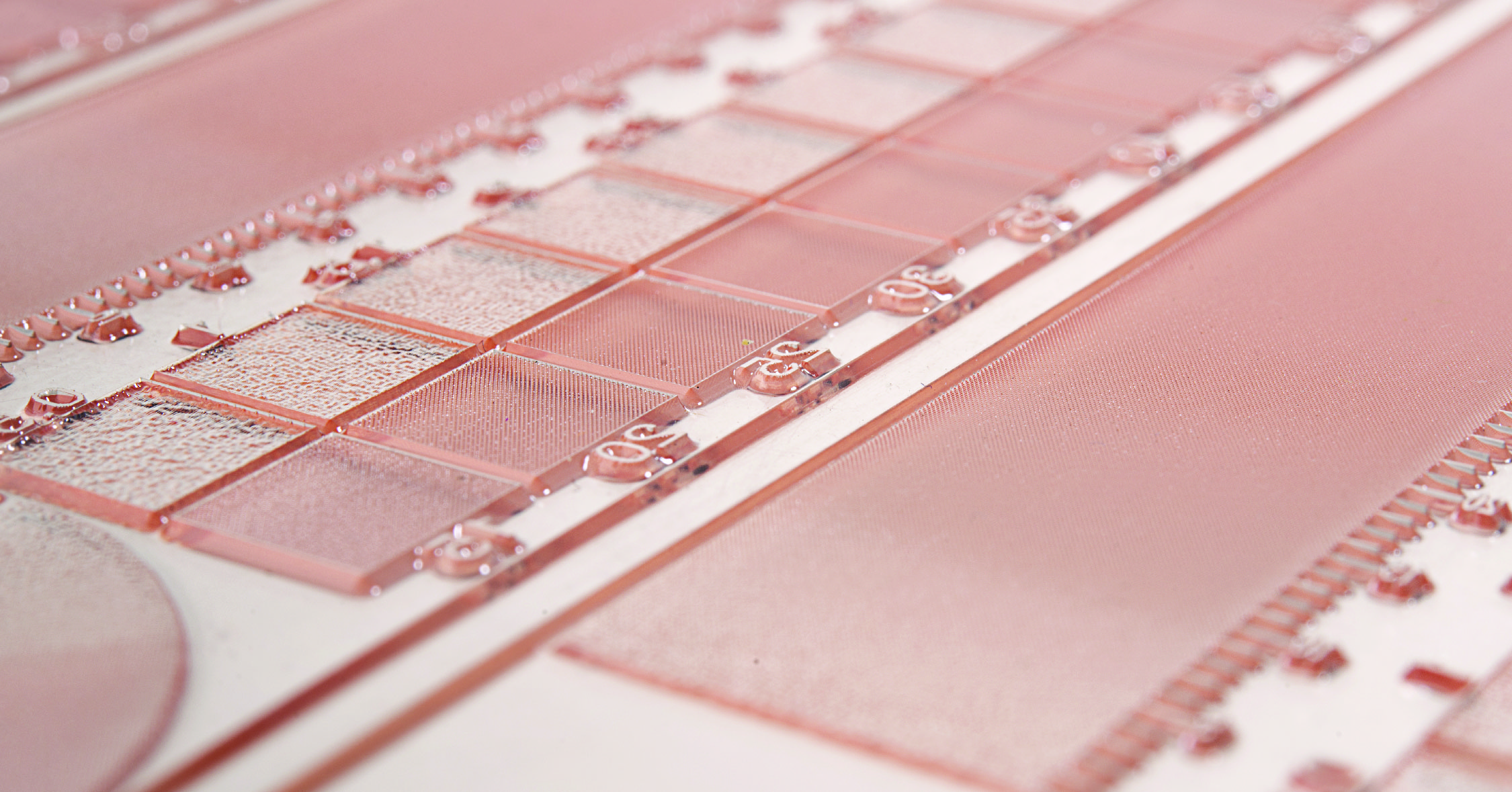

Finally – a plastic-free blister pack

Other Articles You Might Enjoy

Sustainability Snacks: Labeling a Smarter Future with UPM Raflatac

In this month’s episode of Sustainability Snacks, we are sitting down with Tyler Matusevich to talk about how Forest Film, is moving UPM Ralatac forward in their quest to labeling a smarter future beyond fossils. Watch Now!

How Flexographic Printing Can Support Sustainability Initiatives

When we discuss packaging and sustainability the focus is often on the packages end of life; it is recyclable, compostable or made from PRC content? What can easily be missed is the importance of the printing process itself, particularly from the consumer perspective. In packaging today, flexographic printing and rotogravure printing are popular for long-run, high-volume printing, however, flexographic printing can provide sustainability benefits and be more cost effective for shorter runs.